Beginner’s guide to industrial automatic screwdriver feeder

Through technological advancements, multiple devices and machines are invented to add comfort and ease to our lives. For instance, feeding and locking screws manually can be tiring for the workers and the manufacturer. Manual labor reduces work efficiency and capacity. The solution to this problem is the automatic screw feeder driver for extensive use in your shop or working area.

What is Automatic Screwdriver Feeder?

An automatic screwdriver feeder is a small automatic machine with an automatic mechanism to complete the tasks like taking, placing, and locking screws. The screw dispenser machine consists of two parts;

• The Feeding Device: It is responsible for screening and screws

• The Electric Screwdriver: It is responsible for the taking and tightening of screws.

The Automatic Screw Feeder Machine Manufacturer will increase your work efficiency and reduce the cost of labor.

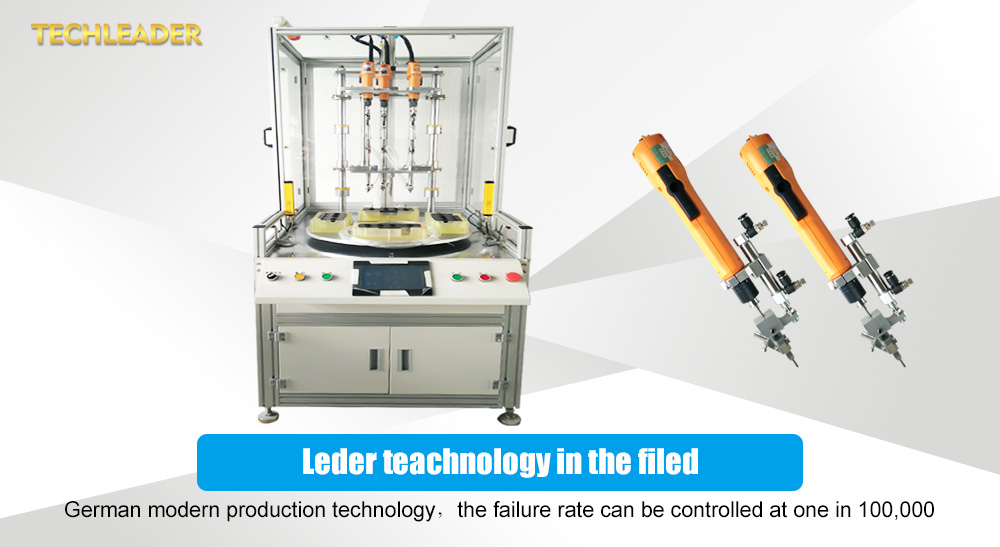

Automaitc Screw Feeder Machine

Screw feeder driver is of two types;

• Handheld Automatic Screw Feeder Driver

This type of Screw Feeder Driver is small and lightweight, making it easy to handle the machine. All you have to do is aim the screwdriver at the screw hole and lock the screw.

The best part is that you don’t have to wait and put in a screw to go for the next screw hole. The screw feeder will automatically transfer another screw to the screwdriver after you lock in one.

The handheld automatic screw feeder drivers are used mainly in assembly lines of household appliances, electronic products, toys, etc.

• Fully Automated Screw Feeder

The fully automated screw feeder driver removes the human labor required in the handheld automatic screwdriver machine. It consists of a screwdriver attached to robotic, automatic control, a multi-axis workbench that performs assembly line operations automatically. The rest of the functions are similar to the handheld screw feeder.

Understand Your Product

When you are considering installing an automatic screw feeder system in your assembly process, you need to ask yourself this question.

“Will this be practically beneficial for assembling my product?”

It might sound senseless to ask this question, but you need to analyze your product’s requirements. Chances are, you might not even need it.

Consider this; we know that assembly automation screw feeders present large numbers of the same type of screw at a fast pace to a fixed point. Now, what if your product only requires three screws but all of the different sizes. You’ll need three automatic screw driving system manufacturers, which will cost you a lot and probably won’t have much of an impact on your assembly speed.

On the contrary, your product might require thirty to forty screws of the same kind. A single screw feeder machine can do your work in a short amount of time.

Calculate Your Benefits

You can calculate the total benefit of your screw presenter from any automatic feed screwdriver system manufacturer like this;

Total Benefit = (Time savings per screw) x (Number of screws)

Most probably, the automatic screw feeder will cover its investment cost in a reasonable amount of time and also generate your expected returns. If so, then an automatic screw feeder driver is the right choice for your company.

Set Your Screw Feeders in the Right Position

Besides making sure you are using the screw feeders on the right product, you also need to set its position. You need to consider the following points when you select the position for your screw feeder in the assembly process;

• It needs to work seamlessly with the assembly process

• You operator must be able to reach it ergonomically and comfortably

• It must be quick to refill and keep in decent working order.

It’s critical to locate your screw presenter and your operator’s workstation in the proper position, whether you’re manufacturing in a line, cell, or hybrid phase.

In general, it’s safest to position your workstation closest to the product’s next and last assembly stations. This ensures that the product will move down the line as quickly as possible.

Declines in overall assembly flow quality can counterbalance any increases in operator performance produced by the screw feeder, so it’s crucial to find the screw feeder directly.

Smart ideas for refills

Around the same time, designing your screw dispenser mechanism such that refilling it is easy is a smart idea. Screw presenters may be fed in two ways: locally from an input bin or centrally by piping. Big input bins on local screw feeders mitigate the need for regular refills. When planning the location of your screw presenter device, keep accessibility in mind if at all necessary.

Things to keep in mind when using human labor

Finally, if you’re using human assembly labor, it’s vital to put the screw presenter with ergonomics in mind. Awkward assembly conditions cause repetitive motion accidents, resulting in job downtime and treatment expenses.

Place the screw feeder machine in a location that minimizes the amount of pressure on your employees’ knees and backs when picking up, spinning, and fastening screws to avoid repetitive motion injuries.

Automatic screw presenters will help the assembly phase go nearly 50% quicker than it would if you used open bins or shaker trays. However, to realize these productivity benefits, it’s important to plan the screw supply operation carefully. Having the best use of your investment in an automatic screw dispenser depends on the machine’s application and position.

automatic screw feeding system manufacturer

Conclusion

Modern manufacturing systems depend heavily on automatic screw presenter machines. Automatic screw presenters can supply large quantities of screws to human or robotic assemblers. Therefore, improving the speed and reliability of an assembly line greatly.

Depending on your application, installing an automatic screw feeder machine manufacturer could be a further step in the growth of the assembly process, especially in meeting the strict requirements of the medical, aerospace, and consumer electronics industries.

Automatic screw presenters can cover their installation costs and achieve a return on investment in applications that involve rapid delivery of large quantities of screws safely, effectively, and frequently.