What are the Benefits of Automatic Screw Feeder Machines?

Businesses across industries are looking to streamline manufacturing processes through automation.

Even a simple procedure such as dispensing screws, that earlier was entirely manual, has a machine in place to save time and ensure increased efficiency. However, often, companies that have an assembly line view an automatic screw feeder machine as an added expense.

If you too are wondering whether you should invest in one, you must read up on the benefits of using an automatic screw feeder machine. We’ve discussed them right here.

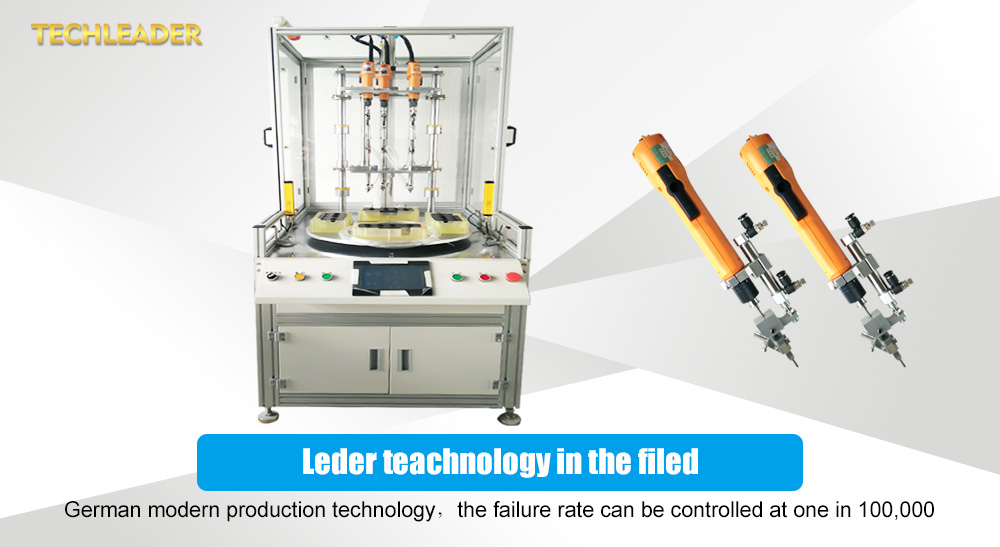

automatic screw feeding system manufacturer

To start with, what is an automatic screw feeder?

As the name suggests, this is an automated tool that supplies screws to the attached screw driving machine. They are extremely easy to operate and can be used by workers or as an attachment with robotic assemblers. There is a sequence controller to manage the supply of screws.

There are different screw feeder formats available on the market. Select models combine a screw driving and screw feeder mechanism, while others only feature the screw feeding function.

An automatic screw finder finds application in assembly lines that handle a large volume of screws daily. They are common in the aerospace, electronics, medical and automobile industry.

The benefits of automatic screw feeder machines

It allows for automation. This is by far the most important benefit of using an automatic screw feeder machine. It dispenses with the need to employ a person to pick up, place and fasten screws. It increases the speed of the assembly line delivering roughly 2-3 screws per second.

Increased production capacity. An automatic screw feeder machine cuts the time required to complete the assembly process. Besides, it also eliminates worker fatigue. If a worker gets tired, he may need a break. It might also affect his ability to perform resulting in inconsistencies along a product-lineup.

Improved product quality. Featuring interchangeable parts, automatic screw feeder machines are designed to work with different screw types and dimensions. Thus, it allows for greater flexibility and can be customised to meet the requirements of precision and detailing unique to every product line.

The feeder supplies the screws in a systematic fashion – they are oriented in the correct direction and at the right angle. Models with an integrated screw driving features, fasten the screws in place. It automatically sorts and picks out the size and type of screw needed. It greatly lowers the chances of a mistake or a rework, thereby ensuring the highest level of quality control.

Great return on value. Their efficiency and safety justify the cost of a quality screw feeder machine. The time saved and increased production capacity covers the installation costs. Not just that, a single machine can handle what might have been done by multiple workers. This reduces the overheads in terms of hiring manpower.

Installing an automatic screw feeder machine is the most practical decision if you want to scale your manufacturing process. A common complaint is that it requires additional space, but with compact designs it is possible to fit this tool in a limited space too.

automatic screw feeder machine manufacturer in china

Choose an automatic screw feeder machine from a reputed dealer and get the best value for money.

For more about automatic screw feeder machine,you can pay a visit to china automatic screw feeder machine manufacturer Huizhou Shengyang at https://www.automaticchina.com/about-us/ for more info.