Beneficial Applications of an Automatic Screw Conveying Machine

Automation has become necessary in every field of life. It has certainly made things easy for humans and it gives higher precision and efficiency. The same is the case with screw conveyor machines. Screws are used in everything and they come in several different shapes, sizes and materials. It requires focus to work with them and it can be tiring if there are several screws to be put in. But automatic screw feeder machine manufacturers have offered a viable solution. This device is ideal for use in any kind of assembly, production, or manufacturing. It can be utilized for personal projects to assembly line production.

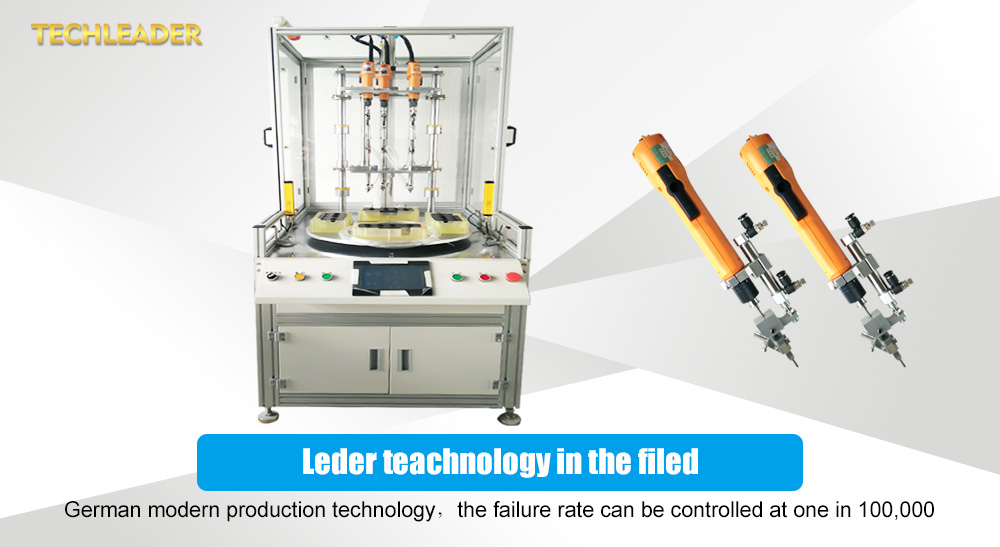

The fully automated screw feeding machines work by sorting a bulk of screws and then sending them into a constant stream to be put in quickly. This shaves of valuable seconds with each screw as there is no need to pick, pint, place, and lock in the screws one by one. This feeder can be attached with an automated screwdriver to make it an even smarter and effective combo. This way, the user does not have to manually lock in each screw. With this device, the screws can be placed directly placed into the hole and with slight pressure, they are locked n place.

Automatic Screw Feeding Machine

Applications of an Automated Screw Conveying Machine

There are so many applications of the automatic screw feeder system. Some major applications of this remarkable machine are mentioned here:

In the Assembling of Medical Devices

Medical device manufacturing and assembly require precision and efficiency at all times. They have to be perfectly built according to certain criteria. With manual assembly, it is not possible to maintain the same standard with large-scale production. But automated systems allow perfection as well as efficiency. All these life-saving devices have one thing in common. Screws! They play an important part in the manufacturing of these devices. Almost all medical device manufacturing or assembly businesses use an automatic facility for screw feeding and driving. As the assembly of several products requires an equally greater number of screws, the assembly automation screw feeders systems are perfect for delivering a large number of screws in a continuous stream to save time and improve work output.

In the Assembly of Aerospace Components

There are many beneficial applications of this automated machine in the aerospace industry too. All the machinery and part of airplanes or helicopters are assembled using screws of all sorts and sizes. These parts are quite sensitive and need to be assembled perfectly. They cannot be manufactured or assembled manually as even a minor human error could risk human life as well as the loss of highly expensive or proprietary machinery. To eliminate all such risks, automation of the assembly or manufacturing process is necessary. Using the automated assembly devices provided by reliable and authentic automated screw driving system manufacturers is the only course to take. This automated device is perfect for accomplishing this sensitive task.

In the Assembling of Electronic Appliances

In our daily life, we utilize so many machines that are assembled using screws. These screws are put in to assemble many different parts in one functioning machine. These appliances are assembled in larger quantities by using automated assembly devices such as screw feeders and drivers. The screw conveying machines make it much easier to work in a continuous stream. They are ideal to reduce labor costs and work hours. It benefits the bottom line of the production and manufacturing companies a lot. The automatic feed screwdriver system manufacturer can customize the device to be used as a fixed machine or in the form of a robotic arm. This facilitates the assembly lines to produce or manufacture various products perfectly and in a timely fashion.

All these applications of the automated screw feeder machines make them crucial for the manufacturing industry. This device can be customized to follow any specific set of requirements and then reconfigured to adapt to the production requirement of another item. This reusability feature is ideal for the production plants that are working to assemble more than one product or appliance. The cost of this device can be recovered in the form of increased output and efficiency within a few months.

automatic screw feeding system manufacturer

Benefits of Using Automated Screw Feeder Systems

Precision

For the assembly automation of sensitive or micro hardware, it can be hard to put in screws by hand. It will also risk the quality of the assembled product with human error. The automated systems eliminate this risk and deliver precision to the nth degree.

Perfection

Putting in screws by hand is difficult especially with smaller screws. They are hard to handle and put in place to be locked in. Whenever there is a miss, the screw could get lost or make scratches on the surface near the screw hole. This can damage the perfect outlook of the product which is considered a damaged unit. Any imperfections whether they are scratches or poorly locked screws can be easily avoided by an automated machine.

Efficiency

Locking screws one by one is a slow process. They can be stressful for hands and eyes when done for long hours. A tired worker is more likely to make mistakes that is why the automation of this process is considered beneficial as it eliminates hours of tedious work and removes the risks of any potential errors.

Cost Reduction

With an automated system, there is a reduced requirement of labor and all associated expenses. Since, the automatic screw feeding and screw driving machines are saving time, effort, and manual labor, they reduce the manufacturing costs a lot while providing higher quality products. Any production line with this asset can easily make a name for itself in the market. The ROI on these automated machines is covered within a few months allowing the bottom line to soar higher.

On top of all these great benefits, the automatic screw feeder machine manufacturers are also offering customization of the machine to fit individual requirements. This makes the devices even more appealing to those who would like to upgrade quality and revenue in one stroke.